Projects & Maintenance Services of Illinois was incorporated in February of 2008 by husband and wife team Bill and Rose Murry. Bill is certified in welding inspection and is a Certified Plant Maintenance Manager. He has 45 years of welding experience and 33 years plant maintenance experience.

Demolition

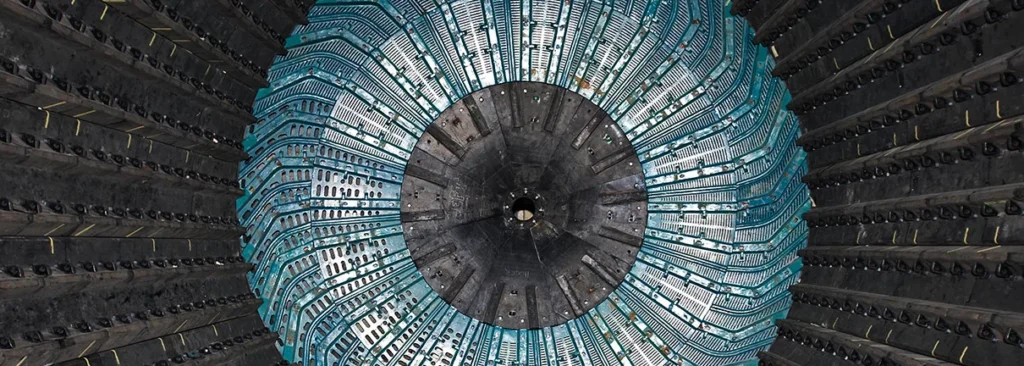

Every mill is unique! Experience from over 8,000 mills worldwide, combined with the market’s most comprehensive offering, means that we can select the optimal mill lining solution for your specific mill.

Performance targets:

Improved sustainability

Long-lasting, high-performing liners designed with sustainability and safety as top priorities

Increased uptime

Shorter and fewer maintenance stops

Lower maintenance costs

Reduced cost of operation, quick and easy maintenance

Optimized throughput

Maximized yearly production

Our People

Meet a few of the problem-solvers and difference-makers who are making an impact wherever they go.

Our Leaders

Meet the leadership team behind one of the world’s most successful 100% employee-owned companies.

Join Us

Be a part of something big. Find your next job and build your story at Burns & McDonnell.

Features

Continuous improvement

A mill lining is a customized wear part. Identifying the appropriate type of lining and design is vital for optimizing mill throughput and total grinding costs, including costs for energy, grinding media and maintenance. Furthermore, the design must be constantly optimized to meet your needs. We work closely with our customers and carefully follow their process to make sure the lining we supply is always optimized for current operating conditions.

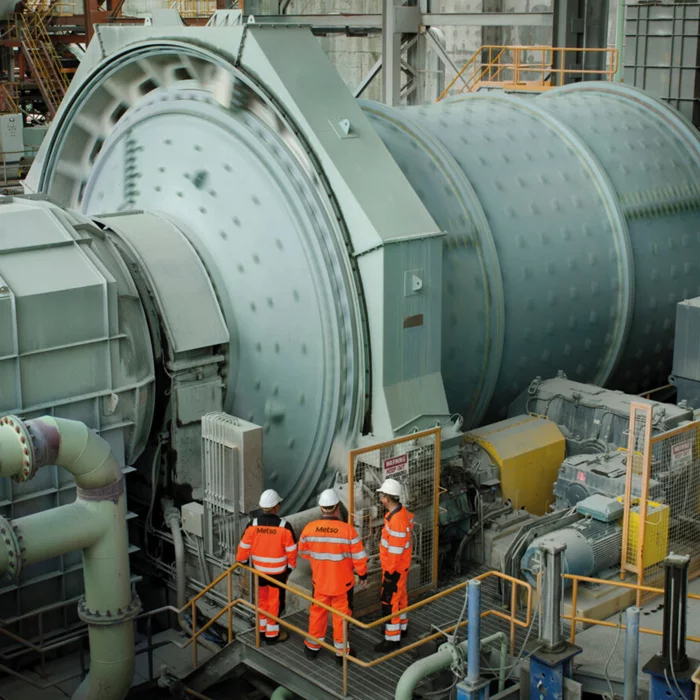

Metso offers mill linings with materials and designs optimized for each specific application. We can design and supply mill linings for all types of mills – for Metso mills as well as for competitor mills – and for all parts of the mill. Our wide product range, innovations, knowledge and experience makes us unique. Our approach to lining design is focused on grinding performance, mill uptime and safety/sustainability.

Safety first

All Metso wear parts are designed with safety as the top priority. We believe that all accidents can be prevented, and we are committed to taking responsibility for our own safety and for the safety of others. Workers’ safety is improved by constant development of tools and methods. Installations can be carried out in a safer way by lighter, wear resistant components, guiding markers, Metso Liner Position System and components with a perfect fit.

Our unique attachment system, developed for Megaliner mill liners, is an invention which have made a great difference for workers’ safety. Liners are placed by the liner handler operator alone and the bolts are inserted from the outside of the mill.

Local support and global expertise

At Metso, cooperation with our customers and availability to offer support and service are of key importance. We have local support close to our customers, several expertise hubs as well as research facilities focused on wear parts development.

Metso’s global laboratory network offers unmatched testing and material development. Our wear parts are manufactured in Metso’s global factory network, utilizing the latest technologies and adhering to stringent quality standards. Today we have nine production units focusing on rubber and Poly-Met wear parts and five foundries for metallic wear parts.

Our unique attachment system, developed for Megaliner mill liners, is an invention which have made a great difference for workers’ safety. Liners are placed by the liner handler operator alone and the bolts are inserted from the outside of the mill.

Unique knowledge in grinding

Metso is widely recognized as a technology leader in mill manufacturing, which makes us much more than a service and wear parts supplier – we are true grinding experts. We know the functional parameters, mechanics, kinematics and forces the mill is subjected to in operation. Thinking long term already when buying a mill provides greater opportunities to achieve lower maintenance and operating costs. This, in combination with knowledge about your current operation conditions and targets, is crucial when designing a mill lining.

Materials

Combine for better results

Our ability to combine different materials in the same mill, using each material where it performs the best, enables us to optimize your grinding process and make it more sustainable.

The lining material should be distributed in such a way that the thick portions protect the areas with high wear and the thinner portions are used on the areas with lower wear. A certain lining thickness is required to achieve the desired wear life, and the lining must also have a profile suited to the desired type of charge movement but without occupying too much volume. Moreover, a good lining design will keep a good profile throughout its service life, providing enough traction to sufficiently lift the charge.

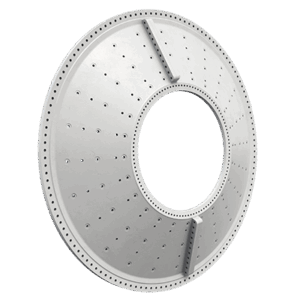

Head linings

As part of a system solution, the head lining is designed with consideration to the shell lining design. All components must be in balance to minimize the number of maintenance stops.

We keep the number of individual parts to a minimum and to ensure that parts do not interfere with each other during installation. Liners that are most subject to wear are made more robust, and whenever possible these high wear parts are designed to be independently replaceable.

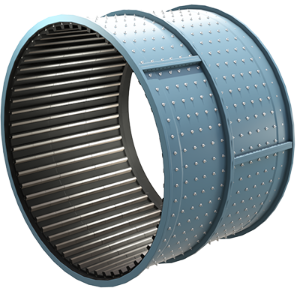

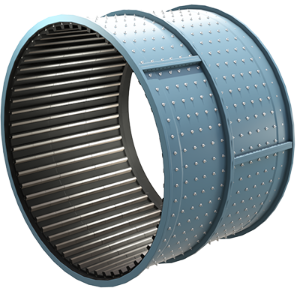

Shell linings

The shell lining has a major influence on grinding efficiency. It transforms the mill rotation into charge motion and both profile and spacing must be carefully selected to suit each specific mill.

When designing a shell lining, Metso considers the type of grinding, mill size and speed, maintenance schedules, safety, impact levels, efficient use of materials, and many other parameters.

Discharge systems

Metso’s wear-resistant rubber-covered or cast dischargers come in two general designs – radial and curved. The larger the mill, the longer the distance the material must travel before being discharged into the trunnion.

A curved discharger design will initiate a flow towards the center of the mill at an earlier stage and ensure that the discharger pan is emptied and ready to be refilled during the next pass through the charge. Prompt removal of material and less backflow will allow the energy to be more efficiently utilized for grinding fresh ore. As less material is recirculated, wear life increases. In addition, increased flow can also contribute to increased throughput and decreased power consumption.

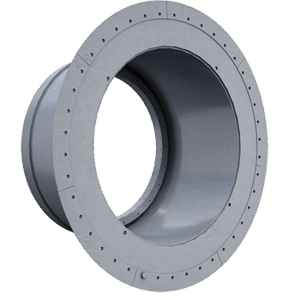

Trunnion linings

Metso trunnion liners are custom-made to protect your mill trunnions from internal wear. Fit is critical, and our trunnion liners can be made to almost any size or shape.

Typical design features include internal spirals or dams to control material flow, flanges for the mounting of trommel screens, the inclusion of threaded holes for jacking screws, inspection ports, etc. Metso trunnion liners are grouped into three categories; One-Piece, Replaceable Sleeve, and Bolted Wear Elements.

Mill trommel screens

Mill trommels, whether used for sizing or scalping, play a vital role in your grinding circuit. Metso’s robust but light-weight trommel frames consist of carefully selected welded profiles that are covered in a protective layer of wear-resistant rubber or polyurethane. Adapting flanges, if required are available to suit the design of virtually any trunnion or trunnion liner interface.

There are two main types of screen panels – modular and customized. The modular trommel panel with snap-on attachment comes in a standard size of 305 x 610 mm. Installation and replacement of the snap-on screen panels is easily accomplished and results in minimal if any impact on mill availability.

- Know all about our project